We are not located in a “High or Extremely High Water Stress” region, according to the World Resource Institute’s Aqueduct Water Risk Atlas. As such, 0% of the water we consume or withdraw is from regions with high or extremely high baseline water stress.

However, we are acutely aware of global and local water concerns, not least because water is an essential resource in the semiconductor manufacturing process. Our CSO holds oversight responsibilities for both our water management strategy and the performance in water management, ensuring these efforts align with our broader environmental objectives and regulatory requirements.

In our efforts to save water, we regularly set and review water conservation goals and monitor water usage in real time at our sole manufacturing site in Gumi. Measurements from our water management system, including water usage and wastewater levels, are reported to our senior management team on a regular basis, alongside the results of our regular ESH compliance evaluations.

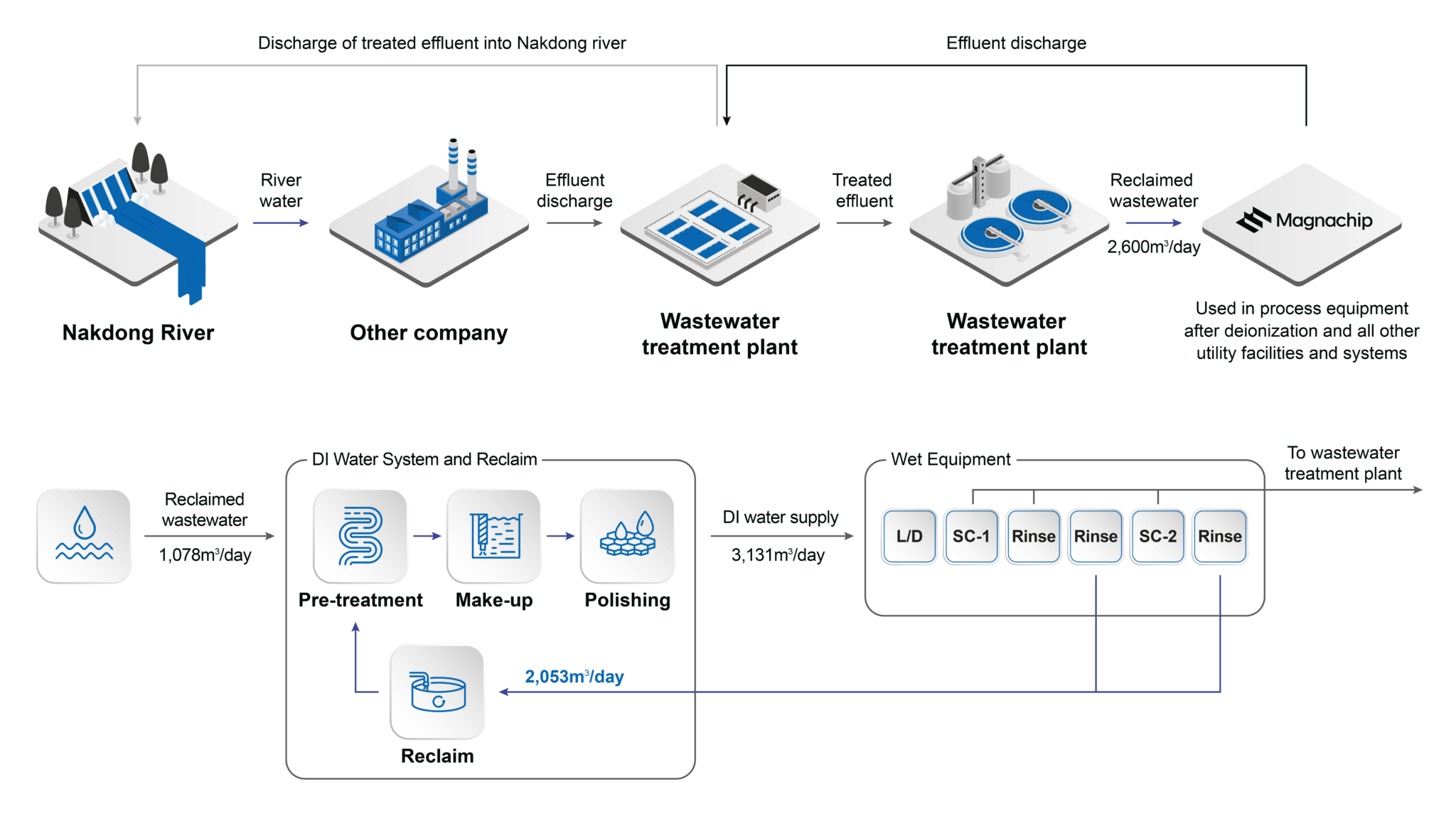

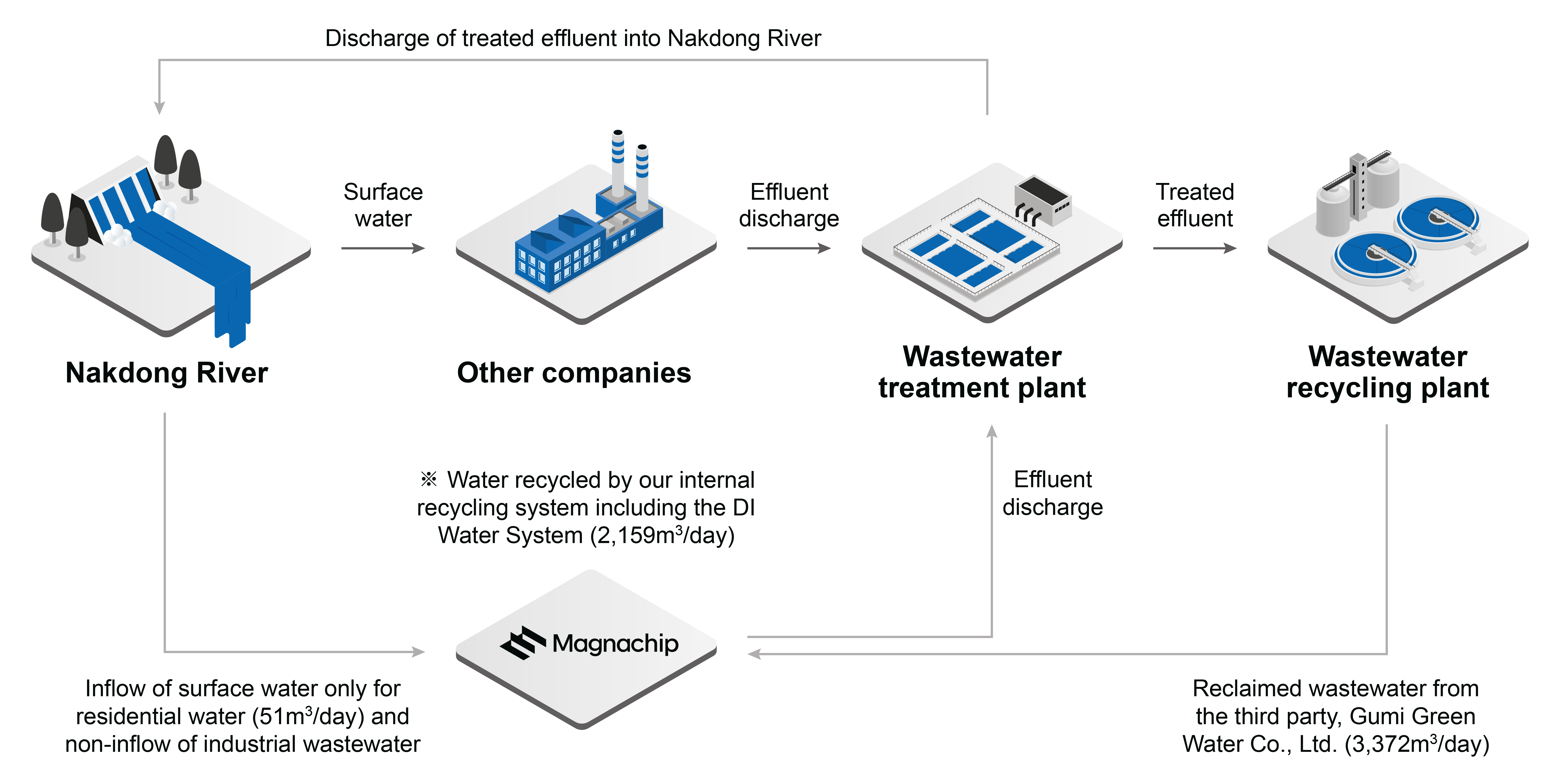

Water reuse and recycling is a key aspect of our water conservation efforts. In 2018, we introduced an integrated water treatment process by establishing an internal recycling system equipped with a deionized (DI) water system in our Gumi plant that allows us to use reclaimed wastewater instead of fresh water in our manufacturing processes. Through this system, we are able to recycle or reclaim almost 100% of the water used in our manufacturing processes, significantly reducing our environmental footprint.

Diagram 2: Water recycling system flow

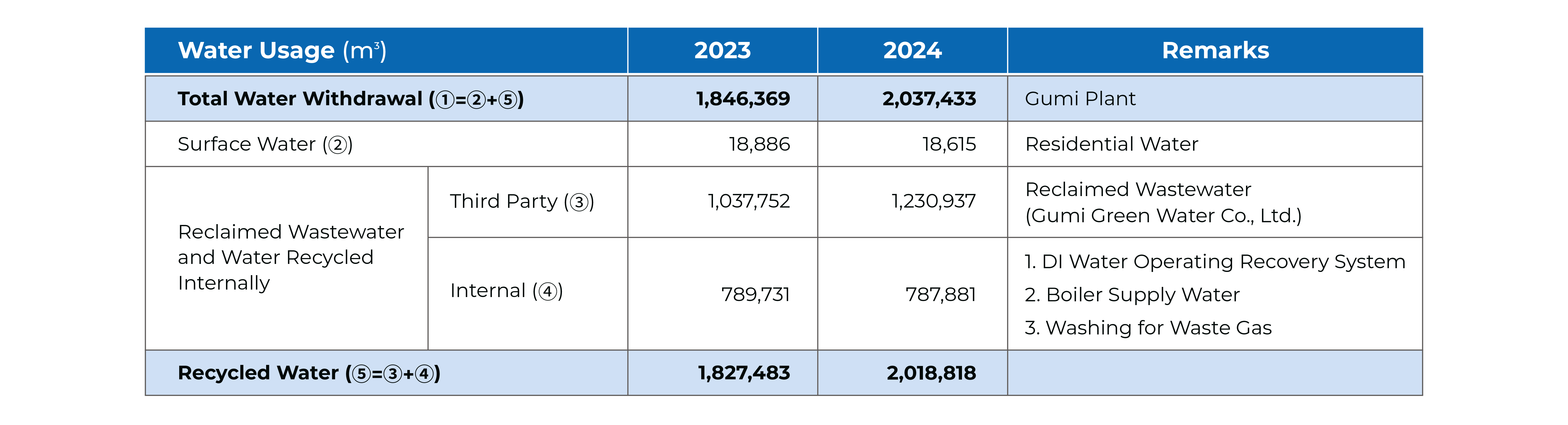

Our total water withdrawal in 2024 was 2,037,433m3 compared with 1,846,369m3 in 2023. The percentage of water we recycled was 99.0% and 98.9% in 2024 and 2023, respectively. Ultrapure water (UPW) for wet equipment is generated in-house through our DI Water System. Approximately two-thirds of the UPW used in wet equipment is recycled through this system. Our UPW usage was 1,136,416m3 and 1,145,138m3 in 2024 and 2023, respectively.

Table 6: Water usage and recycling statistics